We provide the high quality assets and proven technology constructed by qualified manufacturers. For many years, we also operate with the high standard systems and safety level as well as strong, professional, well-experienced local management and team. Out of the three power plants, two power plants utilize sub-critical boilers (2×615 MW) and one power plant utilizes a supercritical boiler (815 MW) which is the first power plant introducing supercritical technology in Indonesia

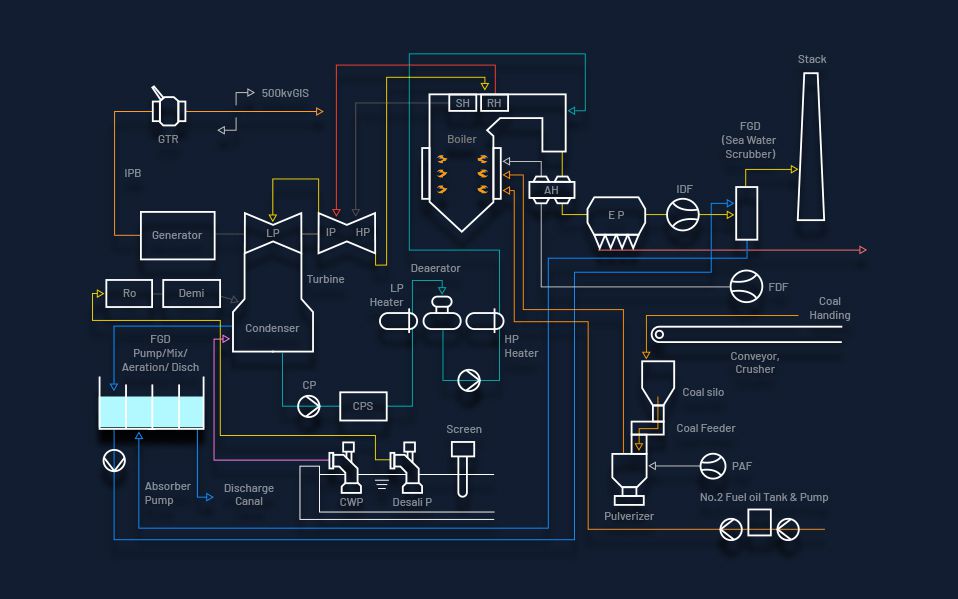

The boiler is of sub-critical type with tangential firing and a reheater, featuring a steam drum and forced water wall circulation. It has a steam generating capacity of 2,300 tons per hour and operates under design conditions of main steam at 538°C and 16 MPa, with reheat steam at 538°C and 3.9 MPa.

The steam turbine is a tandem compound design featuring a dual flow reheating (RH) turbine and double dual flow low-pressure (LP) turbines, with a net capacity of 615 MW.

The generator is a 2-pole, 3-phase type with a rated capacity of 846 MVA and an armature voltage of 23 kV.

The fuel utilized is sub-bituminous coal, known for its lower carbon content and higher moisture levels compared to other coal types. This type of coal is often favored for its efficient combustion properties and lower environmental impact, making it a suitable choice for power generation in steam boilers.

The key environmental features include controlling sulfur dioxide emissions with low sulfur coal and Flue Gas Desulfurization (FGD), managing particulate emissions using low ash coal and Electrostatic Precipitators (ESP), and reducing NOx emissions with low NOx burners.

The boiler is of supercritical type, featuring dual furnace tangential firing with a reheater and a steam separator capable of handling both wet and dry phases. It has a steam generating capacity of 2,630 tons per hour. The design operating conditions include main steam at 538°C and 24.5 MPa, and reheat steam at 538°C and 4.7 MPa.

The steam turbine is a tandem compound design, featuring a combined High-Intermediate Pressure (HIP) turbine and dual flow low-pressure (LP) turbines, with a net capacity of 815 MW.

The generator is a 2-pole, 3-phase type with a rated capacity of 1,045 MVA and an armature voltage of 27 kV.

The fuel used is sub-bituminous coal, known for its moderate energy content and lower sulfur emissions, making it suitable for efficient power generation.

The key environmental features include controlling sulfur dioxide emissions through low sulfur coal and Flue Gas Desulfurization (FGD) technology, managing particulate emissions with low ash coal and Electrostatic Precipitators (ESP), and reducing NOx emissions using low NOx burners.